TRAILER AXLES Factory

The factory covers an area of more than 20,000 square meters with about 100 workers. There are 3 workshops covering an area of 9,000 square meters totally.

The workshop covering an area of more than 3000 square meters is the main manufacturing area. Most fabricate process are finished here. These are CNC lathes, robot welding machines, laser cutting machines, CNC bending machines, stamping machines, etc.

The packaging workshop is also the place where finished products are stored. This workshop covers an area of about 4,000 square meters. All products are assembled or packed here and ready for shipment. This workshop is large enough to hold a large inventory of finished products. Most of the inventory is produced and stored in our company according to customer requirements. Some customers do not have a large warehouse, but sometimes it takes too long from production to receiving of goods. In this case, they require the finished product to be placed in our warehouse, and ship what they need immediately. That solves not only the problem they can't hold too many inventory in their warehouse, but also the problem of delivery time.

The warehouse covers an area of 2,000 square meters. All raw materials, accessories and semi-finished products are placed here. Most of the area is used to store raw materials. We keep stocks of raw materials for many products. When receiving an order, we do not need to spend time to buy raw materials, which shorten the delivery time. We always keep stock for some material when the price is relatively low according to the experience, so that products price is stable even if the raw materials price increases

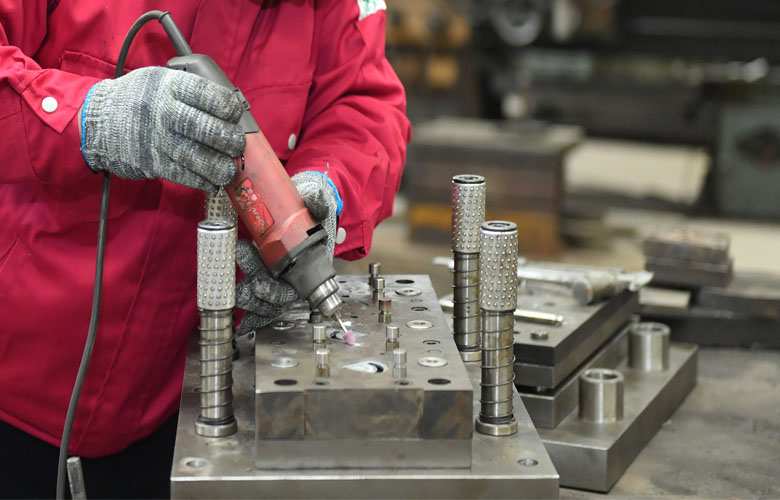

Our company has a separate mould department. Most of the mould can be down by ourselves. It saves both time and money. If the mold is damaged and cannot be continued in production, we can repair it in a short period of time without delaying the production. When developing new products, if the required mold can be completed by ourselves and the cost is within the range we bear, we will not charge you mold fee. You don't need to worry about mold costs.

Haway has enough ability to finish every order well and also help you solve problems and save money too.

- Leave a message you can get

-

- 1.Free sample of one products

- 2.Free drawings based on your requirement

- 3.Catalogue of all our products

- 4.Your inquiry will be replied within 2 hours during working time.

Contact us today for a quote and experience the difference professional engineering makes.

- Name

- Phone

- *Title

- *Content